Is hydrogen a net-zero saviour or a fantasy?

Yogi Schulz has more than 40 years of information technology experience in various industries, including the energy industry; his specialties include IT strategy, web strategy and systems project management. His new book, co-authored by Jocelyn Schulz Lapointe, is “A Project Sponsor’s Warp-Speed Guide: Improving Project Performance.”

Yogi Schulz has more than 40 years of information technology experience in various industries, including the energy industry; his specialties include IT strategy, web strategy and systems project management. His new book, co-authored by Jocelyn Schulz Lapointe, is “A Project Sponsor’s Warp-Speed Guide: Improving Project Performance.”

We've all read articles from enthusiastic environmentalists and climate-conscious political leaders promoting vastly increased hydrogen use. They see more hydrogen production and consumption, especially green hydrogen, as essential to reducing fossil fuel consumption, advancing the energy transition to net zero and addressing climate change.

Is hydrogen, grey or green, a technically and economically feasible replacement for fossil fuels such as gasoline and natural gas? How much of what we read is realistic? How much is enthusiastic fantasy?

The main reasons for the hydrogen eagerness are that it:

- Produces no greenhouse gases (GHG) when burned for energy.

- Is just as versatile as natural gas and gasoline.

- Offers much higher energy density compared to batteries.

- Is the most common element in the universe.

Multiple cost issues offset these advantages. These will dampen the enthusiasm and slow the adoption of various forms of hydrogen.

Comparing hydrogen to gasoline at the pump

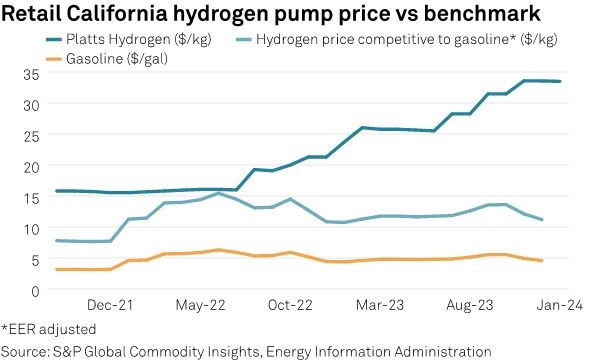

California has made much more effort than most states and countries to offer hydrogen as a low-carbon automobile fuel. Nonetheless, it’s hampered by a lack of reliable distribution infrastructure and continuing high hydrogen prices at fueling stations.

The middle line on the chart below shows the price at which hydrogen is competitive with gasoline as an automobile fuel. The California hydrogen price is now 3.5 times the gasoline-equivalent price.

Source: S&P Global

Because the California hydrogen price has increased to 3.5 times the gasoline price, that’s a massive disincentive for more adoption of hydrogen as a routine automobile fuel. The difference between the two fuels is even higher elsewhere.

Comparing hydrogen to gasoline on the road

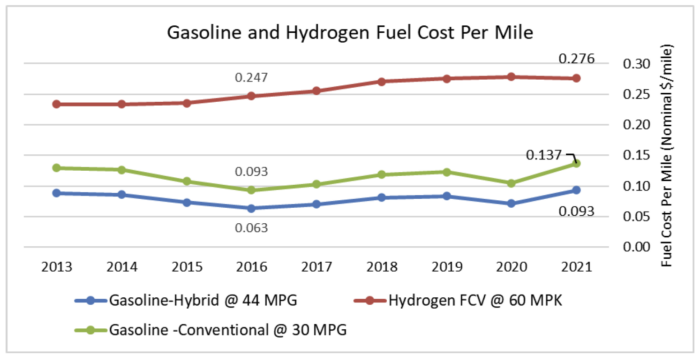

The chart below shows how the higher price of hydrogen almost triples the cost of operating an automobile compared to gasoline.

Source: Stillwater Associates Insights

This high cost differential creates a massive disincentive for more adoption of green hydrogen as a routine automobile fuel. Also, given the limited selection of hydrogen automobiles, gasoline and hybrids tend to have a lower purchase price.

Comparing hydrogen to natural gas production costs

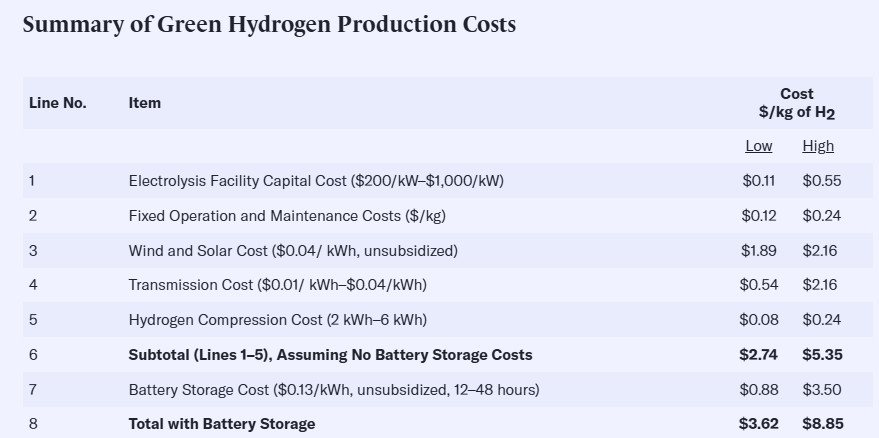

Hydrogen can be produced or manufactured by electrolysis, separating water molecules into hydrogen and oxygen. The product is called green hydrogen when the required electricity is produced without creating GHG emissions. This table estimates green hydrogen production costs. By comparison, natural gas costs only about $0.14 to $0.28 per kg. That’s more than 10 times cheaper. Grey hydrogen, produced from natural gas, costs about $1.06 to $1.64 per kg, as shown in the following chart.

Source: Manhattan Institute

The highest-cost component of green hydrogen production is the cost of electricity consumed by the electrolyzers. Because the cost of electricity is unlikely to decrease materially in the foreseeable future, green hydrogen is unlikely to become competitive with natural gas or gasoline alternatives.

The much lower cost of natural gas and its higher energy density explain why natural gas is widely used and distributed while hydrogen is not.

Comparing the cost of various hydrogen production technologies

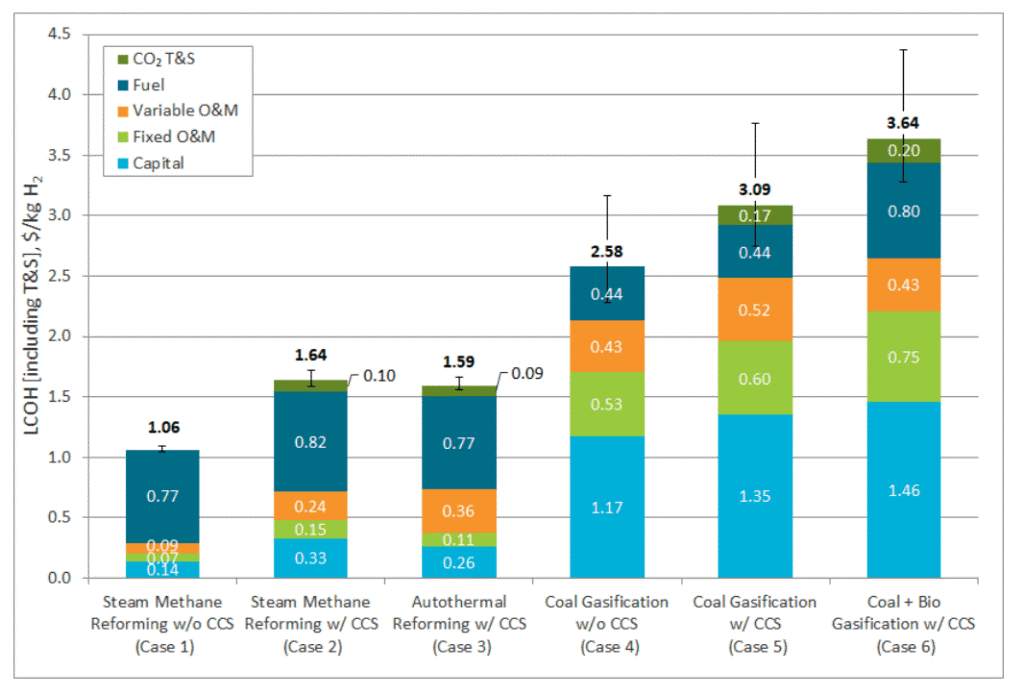

This chart compares multiple alternatives for producing hydrogen as calculated by The U.S. Department of Energy's National Energy Technology Laboratory. Currently, petrochemical production consumes almost all hydrogen as a feedstock.

Unsurprisingly, the hydrogen produced today uses the steam methane reforming approach because it’s the cheapest, despite the associated GHG emissions.

Which hydrogen production method has the lowest cost? Source: Power Engineering

Most of the higher-cost alternatives capture the GHG emissions using carbon capture and storage (CCS). It's doubtful that consumers are willing to pay for the cost of adding CCS to the cost of hydrogen. That reality will slow the adoption of hydrogen as a fuel.

Comparing hydrogen to batteries

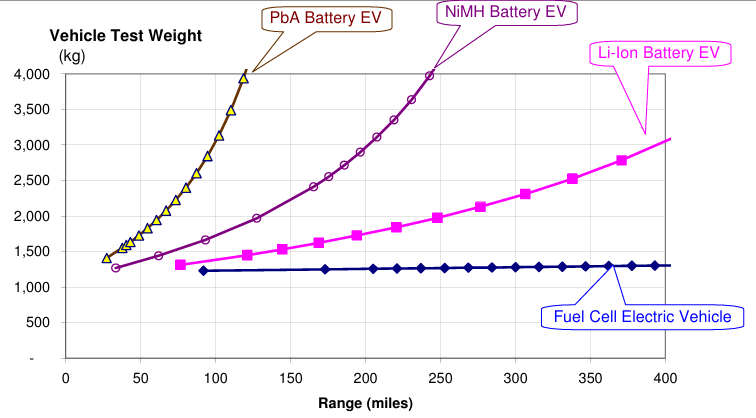

The chart below compares weight when using hydrogen and its tank to produce electricity from a fuel cell to power an automobile to one using lithium-ion batteries.

Fuel Cell and Battery Electric Vehicles Compared. Source: H2Gen Innovations, Inc.

The chart illustrates that hydrogen offers a significant automobile weight advantage over even the best-performing lithium-ion batteries. The difference is due to the higher energy density of hydrogen.

Refueling a hydrogen automobile takes about the same time as a gasoline-powered one. Recharging lithium-ion batteries takes much longer.

Despite these hydrogen advantages, the cost of hydrogen and the lack of refuelling infrastructure means electric and hybrid automobile sales far exceed hydrogen sales.

Comparing hydrogen to fossil fuels

Those who remind us that hydrogen is the most common element in the universe skip over the critical fact that much of the easily accessible hydrogen on Earth exists in molecules bonded with other elements. The most prominent example is water, where two hydrogen molecules are bonded to oxygen.

Creating hydrogen requires breaking those molecular bonds. That breaking requires a facility that consumes a lot of energy.

By comparison, no molecular bonds have to be broken for:

- Natural gas or methane. It occurs naturally in a mixture with other molecules, such as ethane, propane, butane, carbon dioxide and water. Natural gas has to be separated from those molecules in a processing plant.

- It is produced in refineries from the many other molecules found in crude oil. Gasoline must be separated from naphthene, aromatic, asphaltene and water molecules.

While producing natural gas or gasoline is not trivial, it is much cheaper because it requires less energy than producing hydrogen from water.

Comparing manufactured hydrogen to natural hydrogen

Until recently, the consensus among geologists was that the Earth’s crust did not contain elemental hydrogen. Then, the discovery of natural hydrogen seeping into a water well in Mali led to exploration activity looking for natural hydrogen on every continent.

Environmentalists are excited by the prospect of natural hydrogen because it qualifies as green hydrogen. At this point, how big a role natural hydrogen will play in future energy supplies is unclear. Estimates of natural hydrogen reserves vary widely because so few exploration wells have been drilled. The cost of production, processing and distributing this hydrogen remains unclear.

In the best case, natural hydrogen will be cheap and plentiful enough to address all the cost issues described here.

Achieving competitive green hydrogen

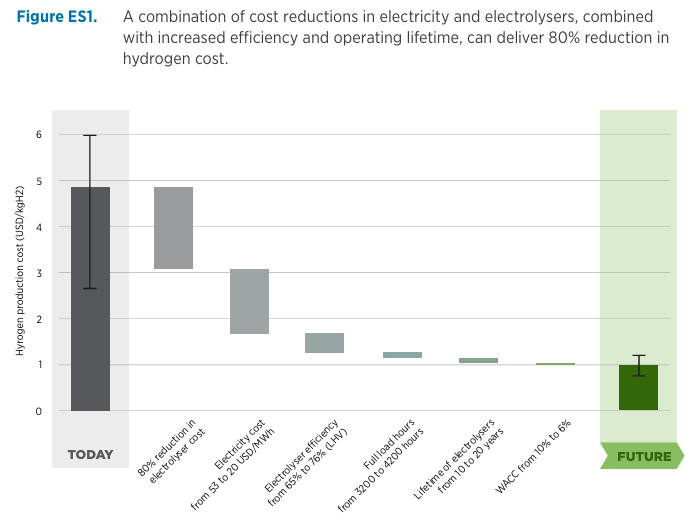

This chart illustrates the cost reductions required to achieve cost parity between gray hydrogen, produced from natural gas, and green hydrogen, produced by electrolysis.

Green hydrogen cost reduction. Source: IRENA, 2020

Achieving cost-competitive green hydrogen will require significant cost reductions, increased efficiency, and an increased operating lifetime for electrolyzers. When these improvements might become available is unknown, even though considerable investments are being made.

Until cost reductions and infrastructure improvements are achieved, the widespread adoption of green hydrogen remains a fantasy because the incremental cost most consumers are prepared to pay for environmental benefits is modest.

R$

| Organizations: | |

| People: | |

| Topics: |

Events For Leaders in

Science, Tech, Innovation, and Policy

Discuss and learn from those in the know at our virtual and in-person events.

See Upcoming Events

You have 0 free articles remaining.

Don't miss out - start your free trial today.

Start your FREE trial Already a member? Log in

By using this website, you agree to our use of cookies. We use cookies to provide you with a great experience and to help our website run effectively in accordance with our Privacy Policy and Terms of Service.